Diesel

Practical Action

Application and choice of engine

To decide which engine is most suitable for a specific application, several factors need to be

considered. The two most important are the power and the speed of the engine. The power

requirement is determined by the maximum load. The engine power rating should be 10-20 %

more than the power demand imposed by the end use. This prevents overloading the engine by

inadvertently adding extra load, during starting of motors or some types of lighting systems or as

wear and tear on the engine pushes up its power consumption.

For example, a generator with a required output of 10 kW (kilowatts) and an efficiency of 75%

would need an engine of the following capacity;

Output requirement

Efficiency

Shaft power requirement

Engine power requirement

10 kW

0.75

10 / 0.75 = 13.3 kW

13.3 kW x 10% = 14.63 kW

As engine power is often given in horse power (1 h.p. = 0.746 kW), choose an engine of size

19.6 h.p. or the next standard size above this figure.

Another important factor when choosing an engine is speed. Speed is measured at the output

shaft and given in revolutions per minute (r.p.m.). An engine will operate over a range of speeds,

with diesel engines typically running at lower speeds (1300 - 3000 rpm) and petrol engines at

higher speeds (1500 - 5000 rpm). There will be an optimum speed at which fuel efficiency will

be greatest. Engines should be run as closely as possible to their rated speed to avoid poor

efficiency and build up of engine deposits due to incomplete combustion, which will lead to

higher maintenance and running costs.

To determine the speed requirement of an engine we again look at the requirement of the load.

For some applications the speed of the engine is not critical but for other applications, a

generator for example, it is important to get a good speed match. If a good match can be

obtained then direct coupling is possible; if not, then some form of gearing will be necessary, a

gearbox or belt system for example, which will add to the overall cost and reduce the efficiency.

Other factors that should also be considered include: cooling system, abnormal environmental

conditions (dust, dirt, etc.), fuel quality, speed governing (fixed or variable speed), poor

maintenance, control system, starting equipment, drive type, ambient temperature, altitude,

humidity, etc. Suppliers or manufacturers literature will specify the required information when

purchasing an engine.

The efficiency of an engine depends on various factors, e.g. load factor (percentage of full load),

engine size, and engine type. Some typical figures are given below. Other power system

efficiencies are also quoted for comparison.

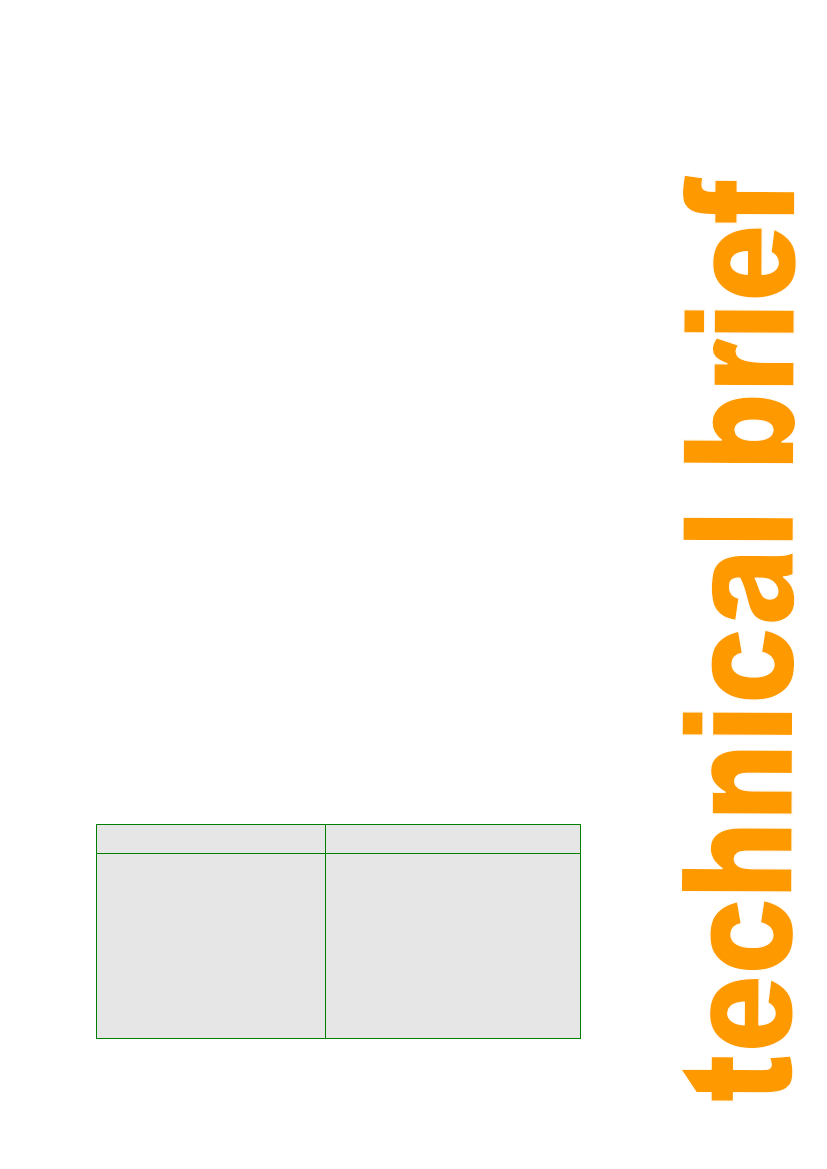

Type of engine

5 kW petrol engine (full load)

5 kW diesel engine (full load)

5 kW diesel engine (20% load)

50 kW diesel engine (full load)

500 kW diesel engine (full load)

Efficiency (as a percentage ) %

15

25

10

35

45

50W windmill (battery charger)

500 kW wind turbine

15

40

5 kW hydro electric system

500 kW hydro electric system

60

85

[Source: The Power Guide, IT Publications, 1994.]

3